Enhancing the Utensil Industry: The Power of Laser Technology

- Pradip Chumkiya

- Jun 15, 2023

- 2 min read

Introduction:

The utensil industry plays a crucial role in our everyday lives, providing us with the tools we need to prepare, cook, and enjoy our meals. In recent years, the industry has experienced significant advancements thanks to laser technology. Laser machines have revolutionized the way utensils are manufactured, offering numerous benefits such as precision, efficiency, and versatility. In this blog, we will delve into the exciting world of laser technology and explore how it has transformed the utensil industry, accompanied by captivating images.

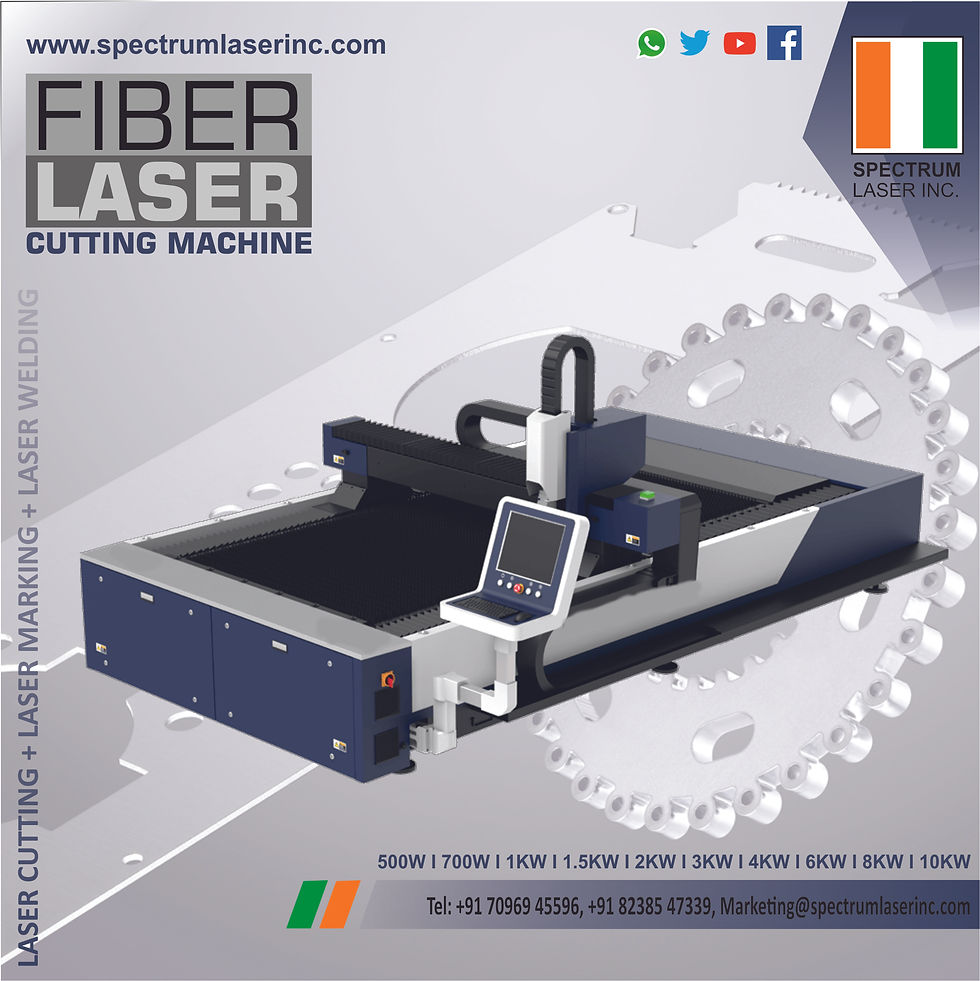

1. Laser Cutting and Precision:

Laser cutting technology has had a profound impact on the utensil manufacturing process. Laser machines are capable of cutting through a variety of materials with exceptional precision, resulting in clean, intricate designs. Whether it's stainless steel, aluminum, or other metals, laser cutting ensures precise and accurate shapes for utensils, enabling manufacturers to meet the highest quality standards.

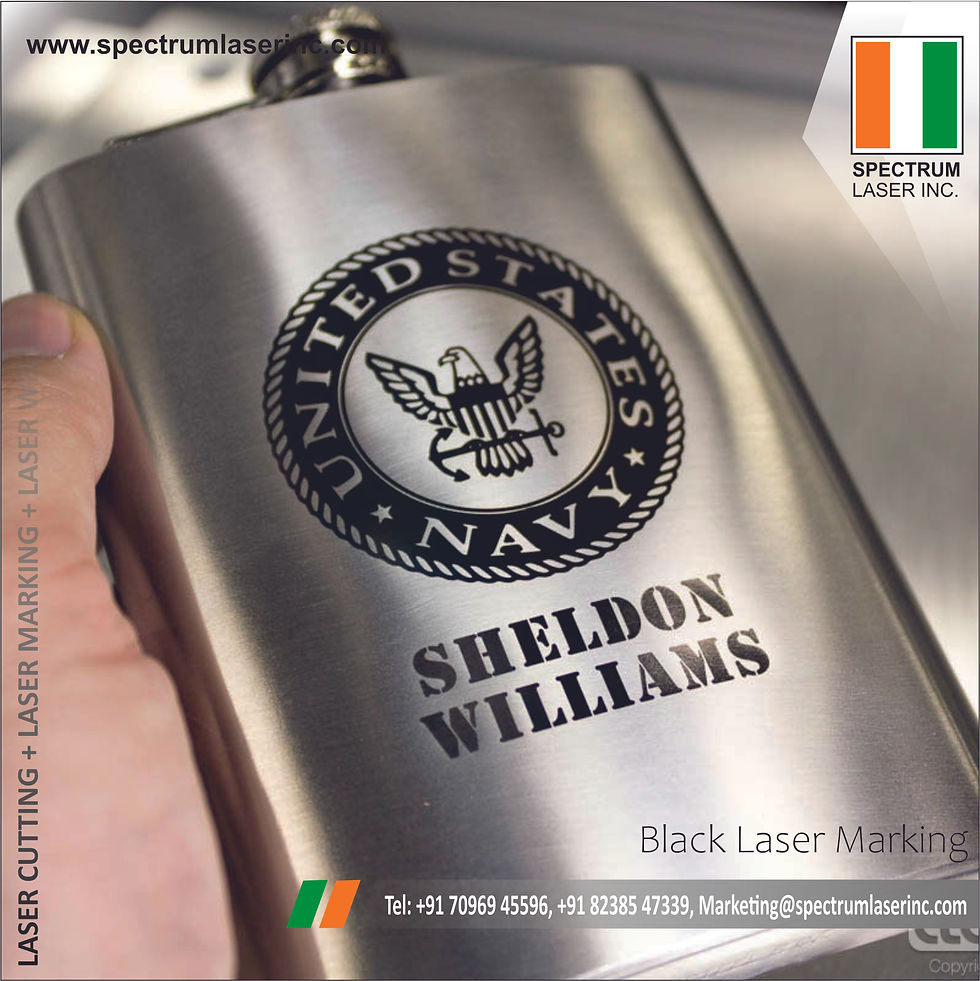

2. Engraving and Personalization:

The ability to personalize utensils has become increasingly popular, and laser machines excel in this domain. With laser engraving, manufacturers can etch unique designs, names, logos, or messages onto utensil surfaces. The precision and versatility of laser technology allow for intricate and durable engravings, elevating the aesthetics and value of the products.

3. Product Identification and Branding:

Product identification and branding are vital aspects of the utensil industry. Laser machines enable manufacturers to mark utensils with permanent identifiers such as serial numbers, barcodes, or QR codes. These markings facilitate inventory management, traceability, and anti-counterfeiting efforts. Additionally, laser technology enables the precise application of brand logos, trademarks, and product information, enhancing brand recognition and customer trust.

4. Enhanced Efficiency and Production Speed:

Laser machines have significantly improved the efficiency and productivity of the utensil industry. Compared to traditional methods, laser cutting and engraving offer faster processing speeds, reducing production time and costs. With the ability to automate processes, laser machines enhance workflow and increase overall output, allowing manufacturers to meet growing market demands.

5. Material Versatility and Flexibility:

Utensils come in various materials, ranging from metals to plastics. Laser machines exhibit remarkable versatility, accommodating different materials with ease. They can cut, engrave, and mark stainless steel, aluminum, copper, titanium, acrylic, and more. This flexibility empowers manufacturers to explore innovative designs, experiment with new materials, and expand their product offerings.

Conclusion:

Laser technology has brought about a significant transformation in the utensil industry, offering manufacturers unprecedented precision, efficiency, and versatility. From precise cutting to intricate engraving and marking, laser machines enable the creation of high-quality utensils while supporting personalization, branding, and product identification efforts. As the industry continues to evolve, laser technology will undoubtedly remain a driving force, pushing boundaries and setting new standards for utensil manufacturing.

I am blown away by the incredible impact laser technology has had on the utensil industry! This blog dives deep into the transformative potential of laser technology, from precision cutting to intricate designs. The informative content and engaging writing style make it a must-read for anyone passionate about culinary craftsmanship. Kudos to the team behind this enlightening blog!